Description: HiperCo27 alloy is a kind of iron-cobalt alloy soft magnetic alloy, which has a certain degree of ductility and market rate among the high and high Curie temperature soft magnetic alloys sold. At the same time, the magnetic and coercivity of HiperCo 50 alloy is slightly better than HiperCo 27 alloy, but the magnetic brittleness of the alloy is similar. In addition, HiperCo 27 alloy does not exhibit the brittleness of HiperCo 50 alloy. The alloy is a soft magnetic alloy with high saturation and high Curie temperature. It has a combination of good mechanical toughness, good ductility and high saturation magnetic induction. Application field: HiperCo27 alloy has been used in applications that require a combination of good mechanical toughness, good ductility and high saturation induction. lPole piece lRelay and magnetic shaft lmotor lDynamo lPole piece lMagnetic bearing

Description: Cobalt chromium tungsten alloy (CoCrW) is one of the (Stellite) alloys. Stalli alloy is a kind of hard alloy that can resist various wear, corrosion and oxidation at high temperature. Commonly referred to as cobalt-based alloys. Stalli alloy was originally a Co-Cr binary alloy and later developed into a Co-Cr-W ternary alloy. Cobalt-chromium-tungsten alloy contains a considerable amount of chromium, tungsten and a small amount of nickel, molybdenum, silicon, carbon, niobium, tantalum and other alloying elements, and occasionally also contains iron. According to the alloy composition, it can be made into welding wire. The powder can be used for hard surface surfacing, thermal spraying, spray welding, etc., and can also be made into castings, forgings and powder metallurgy parts. The main carbides in cobalt-chromium-tungsten alloys are MC, M23C6 and M6C. In the cast cobalt-chromium-tungsten alloy, M23C6 precipitates between grain boundaries and dendrites during slow cooling.

Description: CoCrMo is a cobalt-based solid solution strengthened alloy with excellent strength, ductility and high temperature oxidation ability. It is a non-magnetic cobalt-chromium-molybdenum alloy that can be used to manufacture functional components in the biomedical, aerospace, and high-performance engineering sectors. Application field: lMedical equipment/implants lTurbine engine lIndustrial/Mechanical Parts lPetroleum and natural gas.

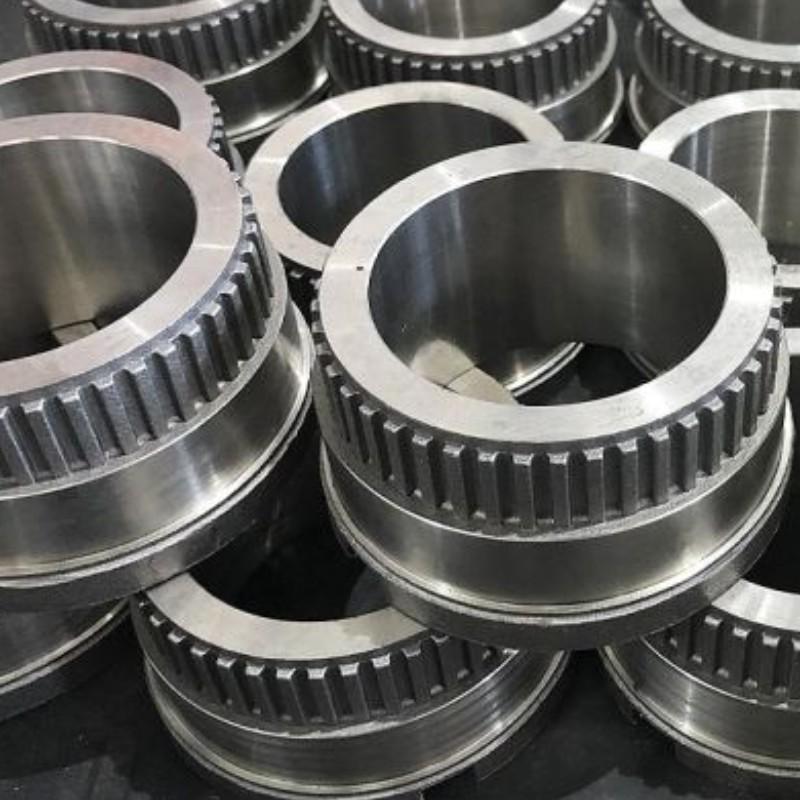

Stellite®12 precision casting, production process of silica sol (Stellite®12, alloy 12, UNS R3012)

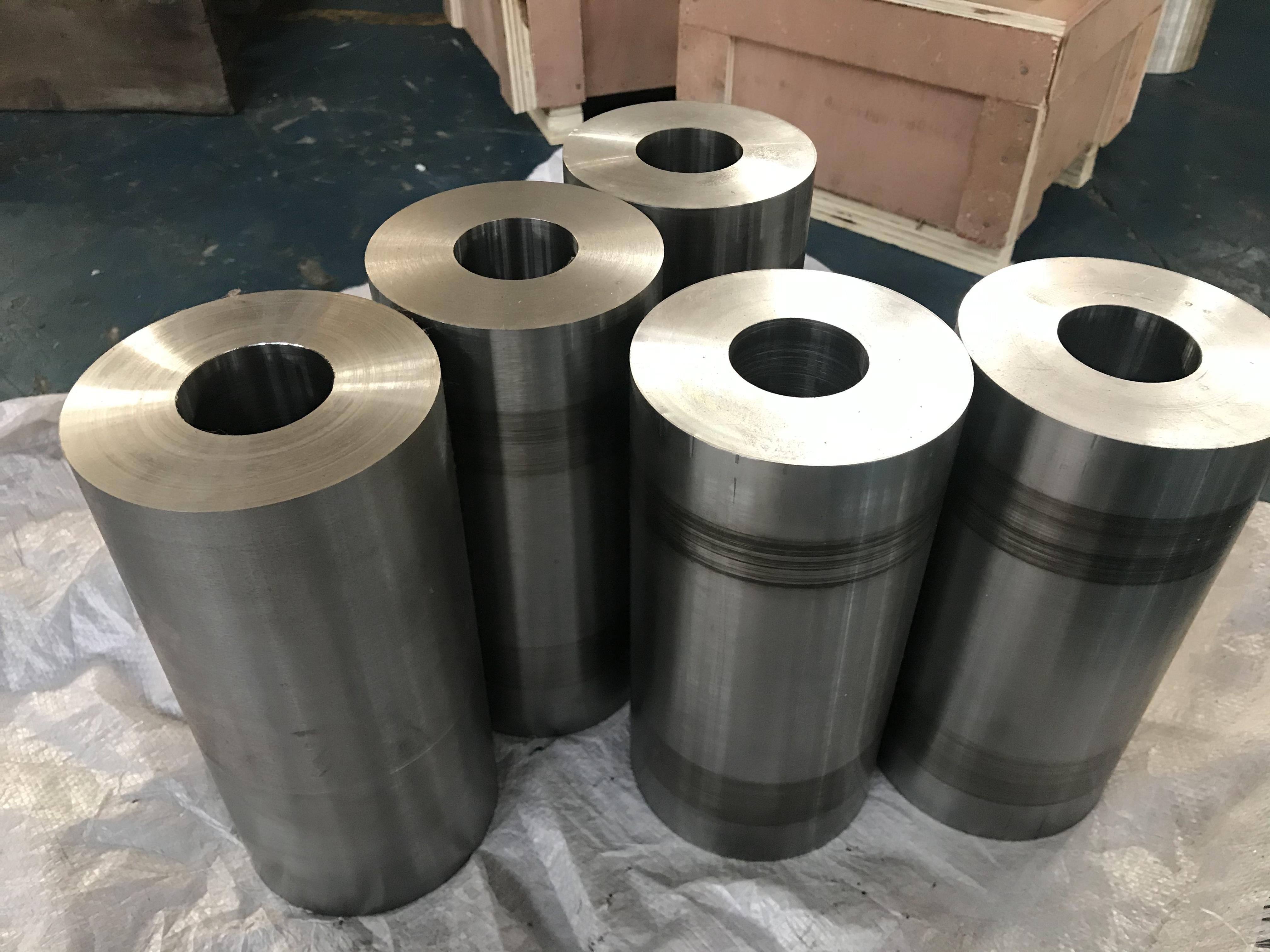

Description: Stellite3consists of complex carbides in an alloy matrix. They are resistant to wear, galling and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix. Stellite3 is an alloy possessing excellent abrasion and corrosion resistance for applications such as pump sleeves, rotary seal rings, wear pads, expeller screws and bearing sleeves. It retains its hardness at temperatures in excess of 760°C.The high carbon content of

Stellite®21 precision casting, production process of silica sol (Stellite®21, alloy 21)