Nickel alloy castings

Alloy738 precision casting

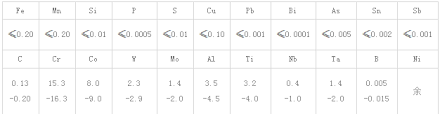

Compared with many high-strength superalloys with lower chromium content, Inconel™ 738 has an excellent combination of high-temperature creep rupture strength and corrosion resistance. In738 is a nickel-based alloy that has undergone vacuum casting and precipitation hardening treatment and has excellent mechanical properties at high temperatures of 1800°F (982°C). IN-738 can withstand the high temperature and corrosive environment in the turbine industry.

Alloy738 application field

• Making turbine rotor blades and guide blades

• Widely used for turbine working blades and guide blades of long-life ships and ground-based industrial gas turbines operating below 900°C.

• It can also be used as turbine parts for aero engines.